Completed Projects

- PROJECT: 17.5MW NEW POWER PLANT

CLIENT: GreenvilleLNG PROJECT: 17.5MW NEW POWER PLANT

- PROJECT: INSTALLATION OF COMBINED CAPACITY OF 28MW VFD DRIVE FOR TRAIN 1, 2 AND 3

CLIENT: GreenvilleLNG PROJECT: INSTALLATION OF COMBINED CAPACITY OF 28MW VFD DRIVE FOR TRAIN 1, 2 AND 3

- PROJECT: ELECTRICAL AND INSTRUMENTATION COMPLETION WORKS (MECHANICAL REFRIGERATION UNIT)

CLIENT: SAVANNAH ENERGY PROJECT: ELECTRICAL AND INSTRUMENTATION COMPLETION WORKS (MECHANICAL REFRIGERATION UNIT)

- PROJECT: ELECTRICAL & INSTRUMENTATION CONSTRUCTION AND INSTALLATION /TELECOM WORK INCLUDING EARTHING WORKS

CLIENT: GRADIENT EMULSIONS AND POLYMERS LIMITED PROJECT: ELECTRICAL & INSTRUMENTATION CONSTRUCTION AND INSTALLATION /TELECOM WORK INCLUDING EARTHING WORKS

PROJECT: 17.5MW NEW POWER PLANT

About the Company

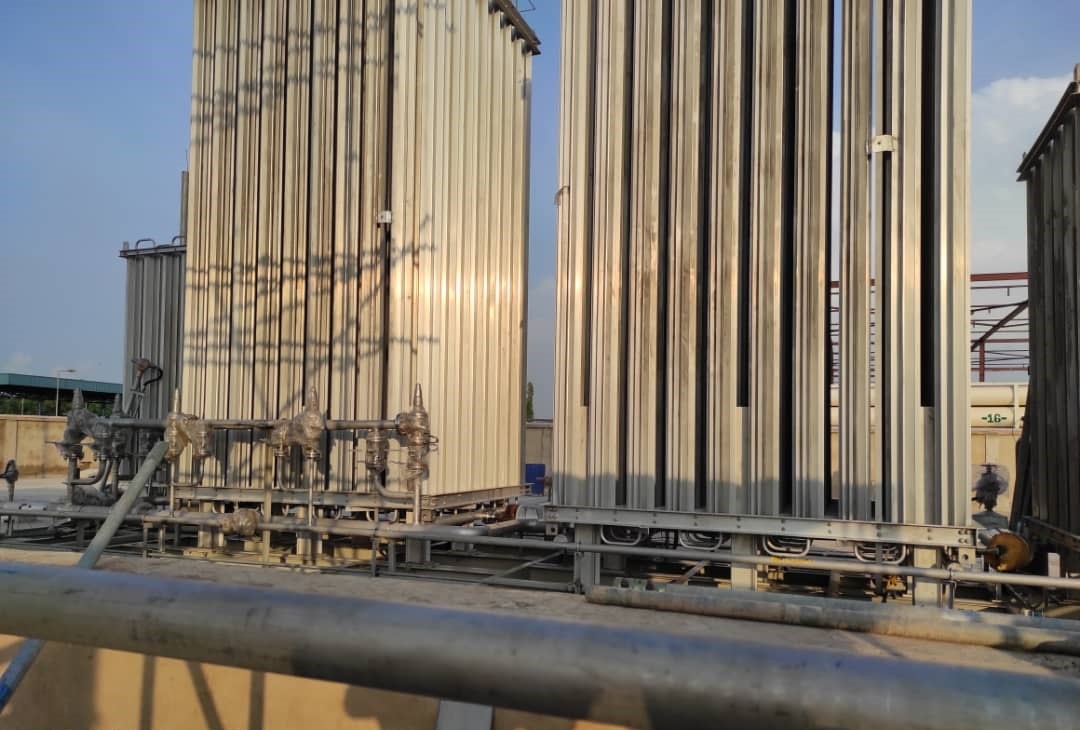

Greenville LNG company Ltd. is the pioneer Liquefied Natural Gas (LNG) production and distribution company in Nigeria using an innovative virtual pipeline system for supply of gas within Nigeria.

The civil construction of our mini-LNG plant in Rumuji commenced in 2015; between 2016 and 2017 Trains 1, 2, & 3 were installed; each train has a capacity of 750MT/day.

Our project consists of two phases;

- Phase 1: three (3) liquefaction trains each with a capacity of 750MT/day, and a total capacity to produce 2250 MT/day.

- Phase 2: two (2) liquefaction trains each with a capacity of 1500MT/day, and a total capacity to produce 3000 MT/day.

The LNG plant in Rumuji currently has three (3) gas liquefaction trains with a total capacity to produce 2250MT of LNG per day; Following the completion of Phase 2 of the project, the plant will have five (5) gas liquefaction trains with a total capacity to produce 5250MT of LNG per day.

Due to the power demands of these projects, Layerfive Integrated was tasked with the responsibility of installing a 17.5MW power plant 2 to support the existing 35MW Plant within the facility. Below are project details

- Installation of 5 Units of 3.5MW Jenbacher Gas Engines

- Installation of SecoGear MV Panels

- Installation of LV Panel

- Installation of generator Auxiliary Panel and ST4 Panel

- Installation of 2 units of 1250Kva Transformer

- Installation of Cooler Fans

- Installation of Louver Fans

- Cable Tray/ Cable Tray Support Fabrication and Installation

- MV/LV Cable laying glanding and Termination

- Pre-commissioning Checks

- Commissioning support

Project Status: Completed

PROJECT: INSTALLATION OF COMBINED CAPACITY OF 28MW VFD DRIVE FOR TRAIN 1, 2 AND 3

About the Company

Greenville LNG company Ltd. is the pioneer Liquefied Natural Gas (LNG) production and distribution company in Nigeria using an innovative virtual pipeline system for supply of gas within Nigeria.

The civil construction of our mini-LNG plant in Rumuji commenced in 2015; between 2016 and 2017 Trains 1, 2, & 3 were installed; each train has a capacity of 750MT/day.

Our project consists of two phases;

- Phase 1: three (3) liquefaction trains each with a capacity of 750MT/day, and a total capacity to produce 2250 MT/day.

- Phase 2: two (2) liquefaction trains each with a capacity of 1500MT/day, and a total capacity to produce 3000 MT/day.

Due to the startup Power demand of the MR compressors, Layerfive Integrated was tasked with the responsibility of installing 28MW Variable Frequency Drive [VFD] for train 1-3 (Train one to three). Below are project details

- Constructability Review

- Installation of three units of 8MW VFD drive

- Installation of 4MW VFD drive

- Installation of MV Panels

- Installation of LV Panel

- Installation of 2 units of 4MW transformer

- Compressor MV Cable termination

- MV Cable Termination at Panel End

- Cable Tray Fabrication and Installation

- VFD building Internal Lighting installation work and External Highmast Light installation work.

- MV, LV and Control system Cable pull, Glanding and Termination

- Transformer Integrity Test

- Installation of cooler Fans

- Installation of Earthing and Lightning protection system

- Installation of cooler Fans Pre-commissioning Checks

Project Status: Completed

PROJECT: ELECTRICAL AND INSTRUMENTATION COMPLETION WORKS (MECHANICAL REFRIGERATION UNIT)

About The Company:

Savannah Energy PLC is a leading African‑focused British independent energy company. Incorporated in England and Wales and are listed on the AIM market of the London Stock Exchange. Our current operations are in Nigeria and Niger, where we are sustainably developing high‑quality, high‑growth projects in both countries.

Layerfiveltd was tasked with the responsibility of carrying out Electrical and Instrumentation completion works on their Mechanical Refrigeration Unit. Details of the project include:

- Cable Tray work covering fabrication and installation

- Transformer Integrity Verification, and commissioning

- MV Cable Termination

- MV Panel Integrity verification

- Earthing Integrity verification

- Process Instrument installation/change out

- Process Instrument calibration and commissioning

- Cable Pull, Glanding and termination

- Integrity Verification of Toshiba TM300mvi VFD for Train 1 and Train 2

- Commissioning of Toshiba TM300Mv for Train 1 and Train 2

- Compressor Motor Commissioning

- Pre-commissioning checks and Process Commissioning

Project Status: Completed

PROJECT: ELECTRICAL & INSTRUMENTATION CONSTRUCTION AND INSTALLATION /TELECOM WORK INCLUDING EARTHING WORKS

About The Company: Gradient Emulsions And Polymers Limited was incorporated in Wuse, Nigeria with Registration Number 1541618. It was registered on 16 Nov 2018 and its current status is ACTIVE. It is fully operational in Nigeria.

Project : Layerfiveltd was tasked with the responsibility of carrying out the electrical, instrumentation and telecom works at their NPA Warri facilities. LAYERFIVE Project scope covers the construction, installation and commissioning of all Electrical, Instrumentation and Telecoms works of the project

Project Details:

- Constructability review works

- Electrical Instrument and control cable installation, glanding and termintation.

- Internal lighting and perimeter lighting installation works.

- Earth grid setup and installation work.

- Fabrication of structures and installation of panels/JBs

- Installation of pumps and motors.

- Installation of fibre optic cable and hookup.

- Tank work

- Commissioning

Project Status: Completed

- PROJECT : WELLHEAD PANEL INTEGRITY VERIFICATION & MODIFICATION AND INTEGRATION OF F&G SYSTEM WITH WELLHEAD CONTROL

CLIENT: SAVANNAH ENERGY PROJECT : WELLHEAD PANEL INTEGRITY VERIFICATION & MODIFICATION AND INTEGRATION OF F&G SYSTEM WITH WELLHEAD CONTROL

- PROJECT: RE-GASIFICATION PLANT-DUFIL PRIMA FOODS PLC

CLIENT: GREENVILLE LNG/DUFIL PRIMA PROJECT: RE-GASIFICATION PLANT-DUFIL PRIMA FOODS PLC

- PROJECT: MR Storage Instrument Installation

CLIENT: GreenvilleLNG PROJECT: MR Storage Instrument Installation

- PROJECT : ELECTRICAL & INSTRUMENTATION WORK

CLIENT: NIGERIAN BREWERIES PROJECT : ELECTRICAL & INSTRUMENTATION WORK

- PROJECT : CALIBRATION/INSTALLATION OF INSTRUMENT/VALVES REPAIR

CLIENT: GRADIENT EMULSIONS AND POLYMERS LIMITED PROJECT : CALIBRATION/INSTALLATION OF INSTRUMENT/VALVES REPAIR

PROJECT : WELLHEAD PANEL INTEGRITY VERIFICATION & MODIFICATION AND INTEGRATION OF F&G SYSTEM WITH WELLHEAD CONTROL

About The Company: Savannah Energy PLC is a leading African‑focused British independent energy company. We are incorporated in England and Wales and are listed on the AIM market of the London Stock Exchange. Our current operations are in Nigeria and Niger, where we are sustainably developing high‑quality, high‑growth projects in both countries.

As an organization that is safety driven, Savannah Energy sought to immediately shut down its wells on event of gas leakage/pipeline vandalization thus LAVERFIVE was tasked to implement this solution.

Project Details:

- Modification of wellhead Control Panel

- Installation of Modified wellhead control Panel

- Installation and Alignment of Dragger Gas Detector (Transmitter and Receiver)

- Installation of F&G Panel

- Cabling Pull, Glanding and Termination

- Pre-commissioning

- Commissioning

Project Status: Completed

PROJECT: RE-GASIFICATION PLANT-DUFIL PRIMA FOODS PLC

About GreenvilleLNG

Greenville LNG company Ltd. is the pioneer Liquefied Natural Gas (LNG) production and distribution company in Nigeria using an innovative virtual pipeline system for supply of gas within Nigeria.

About Dufil Prima Foods Plc

DUFIL PRIMA FOODS PLC was incorporated in 2001 as a private limited liability company at Choba, Port Harcourt, Rivers State. Upon completion of a restructuring exercise the company was converted to Public limited company and became the holding company of the group in year 2008.

The existence of the facility arises due to the growing demand for the product from the consumers of the region and the nation. The objective is to provide fresh and quality product to the consumers.

At this Re-gasification plant project with Greenville LNG at Dufil Port Harcourt Facility, LAYERFIVE INTEGRATED LTD carried out the following functions

◊ Installation of TT, PT, PDT, PG TG and Safety Valves.

◊ Calibration of TT,PT,PDT, PG,PG and Safety Valves

◊ Procurement and Installation of EX Perimeter Light

◊ E&I Material Procurement

◊ LV Electrical and Instrument Cable Pull, Glanding and Termination

◊ Cable Tray and Instrument support Fabrication and Installation

◊ Earthing and Lightning Protection system installation

◊ Pre-commissioning and commissioning

Project Status: Completed

PROJECT: MR Storage Instrument Installation

About GreenvilleLNG

Greenville LNG company Ltd. is the pioneer Liquefied Natural Gas (LNG) production and distribution company in Nigeria using an innovative virtual pipeline system for supply of gas within Nigeria.

On this project, Layerfive Integrated Ltd was tasked with the responsibility to carry out the following

◊ Installation of transmitters and point detectors

◊ Tubing installations

◊ Cable tray fabrication and installation

◊ Instrument cable pull

◊ Cable test glanding & termination

◊ Installation of junction box

◊ Loop check/Pre commissioning checks

◊ Hand over and As-built drawing

Project Status: Completed

PROJECT : ELECTRICAL & INSTRUMENTATION WORK

About The Company: Nigerian Breweries Plc, the pioneer and largest brewing Company in Nigeria was incorporated in 1946 as “Nigerian Brewery Limited". Over the years the company has expanded operations to different locations in Nigeria. The Company was listed on the floor of The Nigerian Stock Exchange (NSE) in 1973, and over the years has received several awards and recognitions in other areas of its operations including product quality, marketing excellence, productivity and innovation, health and safety, corporate social responsibility and sustainability.

Layerfive Integrated Ltd undertook a project in two of their facilities (Ama Enugu and Ibadan) which involved carrying out electrical and instrumentation works at both facilities.

Project details include:

◊ Installation of TT, PT, PDT, PG TG and Safety Valves.

◊ Calibration of TT,PT,PDT, PG,PG and Safety Valves

◊ Procurement and Installation of EX Perimeter Light

◊ E&I Material Procurement

◊ LV Electrical and Instrument Cable Pull, Glanding and Termination

◊ Cable Tray and Instrument support Fabrication and Installation

◊ Earthing and Lightning Protection system installation

◊ Pre-commissioning and commissioning

Project Status: Completed

PROJECT : CALIBRATION/INSTALLATION OF INSTRUMENT/VALVES REPAIR

About The Company: Gradient Emulsions And Polymers Limited was incorporated in Wuse, Nigeria with Registration Number 1541618. It was registered on 16 Nov 2018 and its current status is ACTIVE. It is fully operational in Nigeria.

In this project, Layerfive Integrated Ltd was tasked with carrying out the following responsibilities;

De installation/Calibration and installation of the following;

◊ Pressure safety valves

◊ Temperature transmitter

◊ Pressure gauges

◊ Temperature gauges

◊ Differential pressure transmitter

◊ Safety valve, relief valves

◊ Valve repair/Installation

Project Status: Completed